Client: BOCCI Lighting

2016-2018

Role: Senior Product Developer, Under the creative direction of Omer Arbel

16

16 is formed by sequentially pouring three separate layers of molten glass – in varying opacities – on a horizontal plane. Each layer responds to the indeterminate shape of the previous pour to create a uniquely layered whole. Two of these pieces are then attached and illuminated with an internal LED lamp. The 16 series is available in 4 colours.

21

21 results from a fabrication process in which thin porcelain sheets are draped over an inverted diffuser made of sandblasted borosilicate glass. The thin porcelain skin is allowed to dress the borosilicate core in whatever form occurs naturally – creating a unique shape in every iteration of the fabrication process.Each glass diffuser houses a low-voltage xenon or LED lamp. A strong contrast occurs between the soft, organically distributed light passing through the white porcelain skin and the crisp light moving through the glass diffuser. 21s are designed to cluster in groups, with individual pieces touching each other to create a layered composition in three dimensions.

22

22 is a suite of electrical wall accessories designed as an alternative to the ubiquitous cover plate model. A springloaded barrel system allows an operative component of any sort to pop into a receiving system mudded directly into drywall, or set into a sheet of finish material. The complete assembly results in operative components that sit flush with the surrounding wall surface, without visible cover plates.

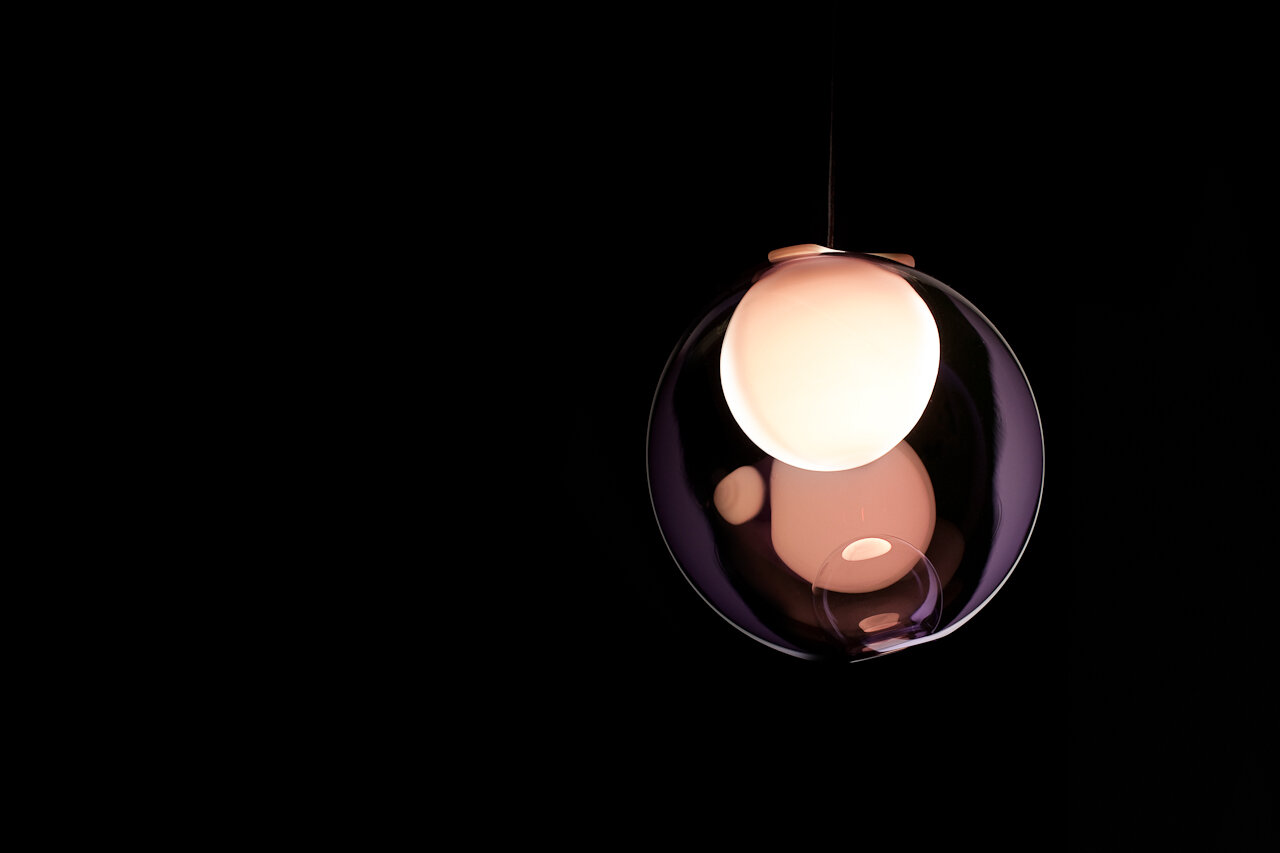

28

28 results from an innovative fabrication process that manipulates both the temperature and the direction of air flow into blown glass. The result is a slightly distorted sphere with an interior landscape of satellite shapes, including an opaque milk glass diffuser that houses either a low-voltage xenon or LED lamp. 28 is available in various suspension methods including clusters, ceiling mount, wall mount.

38

38 pushes the fabrication technique originally developed for 28 to its technical and material limits. A large glass sphere is blown with a multitude of haphazard interior cavities, which intersect and collide with each other in unpredictable ways.

44

Each 44 results from a free pour of molten aluminium into a large canister filled with rock-like modules of resin-impregnated sand, a waste product of conventional sand casting. Low voltage electricity is transmitted through the castings, allowing a light source to be suspended between them without using cables.

76

A vacuum is introduced to a strata composed of hot white and clear glass with copper mesh between; the vacuum causes the white layer to pull away through the embedded mesh, leaving numerous tendrils of white glass suspended within an interstitial space as it goes.

84

A white glass moil is captured inside a fine copper mesh basket and then plunged into hot clear glass. Air is blown into the matrix to gently push the white glass through the mesh, creating a delicate pillowed form that is suspended inside the thick outer layer of clear glass. Sometimes the copper mesh basket folds and crinkles, adding specificity to each piece. Undulations in the exterior shape are a natural consequence of the fabrication process and accentuate the gentle white pillowing below. A low-voltage xenon or LED light source is introduced into the piece, casting a warm coppery hue.

87

Soda water is used to trap air in a super heated glass matrix, which is vertically stretched and folded back onto itself between pegs numerous times. As the glass cools, the folding motion along the grain of the loop turns the entrapped air into microfilaments that give the piece a pearlescent optical quality. A low-voltage xenon or LED light source is introduced at one end of the loop casting light through the microfilaments and registering a gentle gradient.